Introduction: Why Understanding Capacitors Difference Matters

Capacitors are among the most widely used components in electronic circuits, yet misunderstandings about capacitors difference remain common in real production environments.

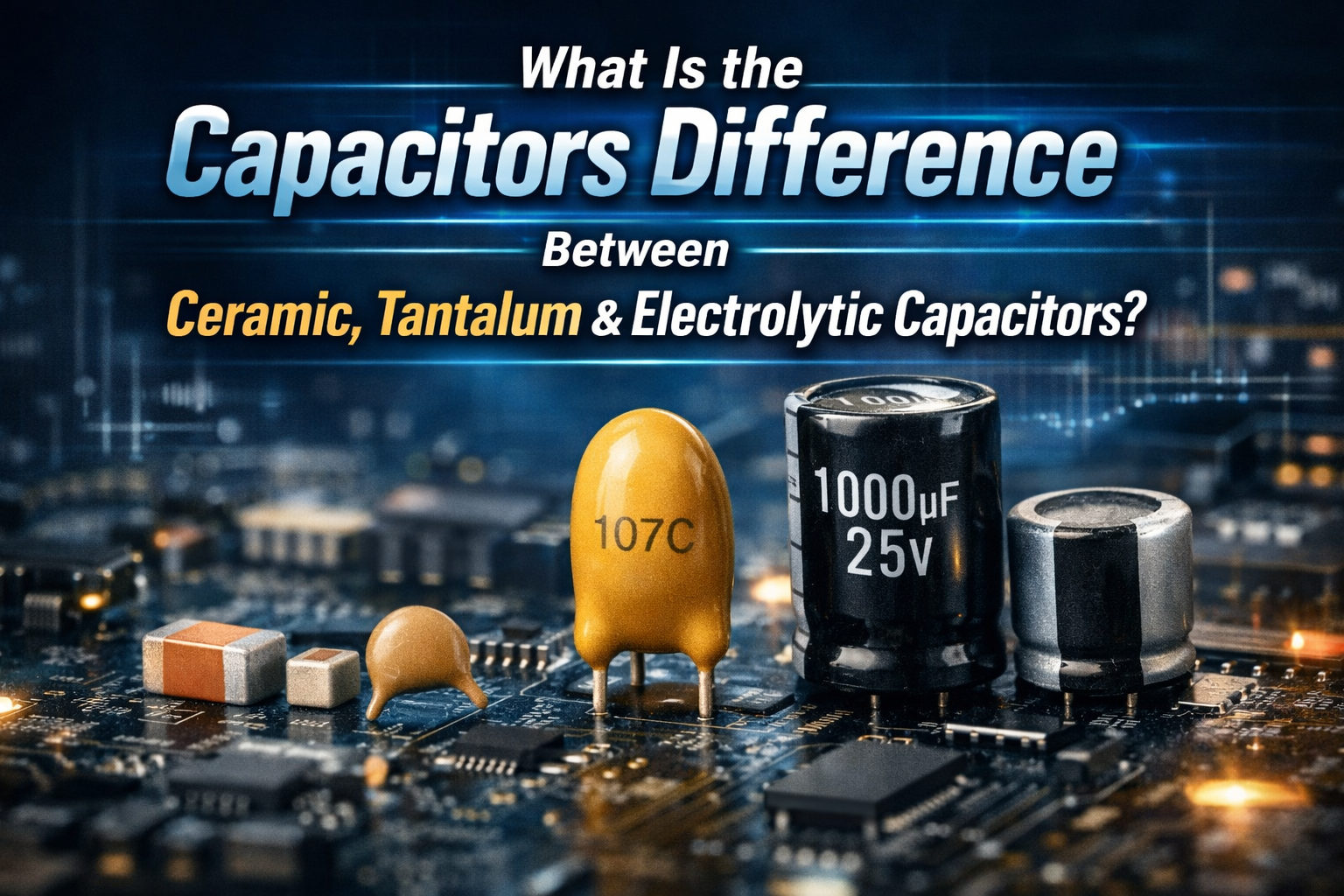

Ceramic capacitors, tantalum capacitors, and electrolytic capacitors perform the same basic function, but their structural design, electrical behavior, and reliability characteristics are fundamentally different.

For engineers and purchasing teams, clearly understanding the capacitors difference between three types is essential to avoid overdesign, cost overruns, or long-term reliability risks. This article provides a practical and application-focused comparison to explain the real difference in manufacturing scenarios.

What Is a Capacitor?

Before comparing different types, it is important to understand the basic principle behind all capacitors.

A capacitor stores electrical energy through an electric field formed between two conductive plates separated by a dielectric material.

The capacitors difference between ceramic, tantalum, and electrolytic capacitors mainly comes from the dielectric material used, which directly affects voltage rating, frequency response, lifetime, and physical size.

Ceramic Capacitors

Structure and Materials

Ceramic capacitors use ceramic dielectric materials such as C0G (NP0), X7R, X5R, or Y5V. They are non-polarized components and typically available in compact SMD packages.

Key Characteristics Showing Capacitors Difference

- Non-polarized design

- Very small size and high mechanical stability

- Extremely low ESR and ESL

- Excellent high-frequency performance

- Limited capacitance compared with other capacitor types

Typical Applications

- Decoupling and bypass circuits

- High-frequency and RF designs

- Consumer electronics and industrial control boards

Practical Perspective

One major capacitors difference with ceramic capacitors is the DC bias effect. Under operating voltage, effective capacitance can drop significantly, which must be considered during circuit design.

Tantalum Capacitors

Structure and Materials

Tantalum capacitors use tantalum metal as the anode and are polarized components. Their design allows higher capacitance density than ceramic capacitors in a smaller volume.

Key Characteristics Showing Capacitors Difference

- Polarized component

- Higher capacitance per size

- Stable performance across temperature ranges

- Lower ESR than aluminum electrolytic capacitors

- Sensitive to over-voltage and reverse polarity

Typical Applications

- Power management circuits

- Automotive electronics

- Medical and industrial equipment

Practical Perspective

A critical capacitors difference with tantalum capacitors is derating. Operating them well below their rated voltage significantly improves reliability, especially in long-life industrial applications.

Electrolytic Capacitors

Structure and Materials

Electrolytic capacitors typically use aluminum with a liquid or solid electrolyte. They are polarized and designed for applications requiring large capacitance values.

Key Characteristics Showing Capacitors Difference

- Very high capacitance range

- Larger physical size

- Higher ESR compared to ceramic and tantalum capacitors

- Limited lifetime due to electrolyte aging

- Cost-effective for bulk capacitance

Typical Applications

- Power supply filtering

- Audio circuits

- Industrial and consumer power systems

Practical Perspective

The most obvious capacitors difference with electrolytic capacitors is lifetime limitation. Temperature and ripple current have a direct impact on service life, which must be evaluated during product design.

Capacitors Difference Comparison Table

| Feature | Ceramic Capacitors | Tantalum Capacitors | Electrolytic Capacitors |

|---|---|---|---|

| Polarity | Non-polarized | Polarized | Polarized |

| Capacitance Range | Low to Medium | Medium | High |

| Size | Very Small | Small | Large |

| ESR | Very Low | Low | Higher |

| Lifetime | Very Long | Long | Limited |

| Typical Cost | Stable | Medium | Cost-effective |

This table highlights the most practical capacitors difference for real-world applications.

How to Choose Capacitors

Choosing the right capacitor is not about selecting the “best” type, but about understanding the capacitors difference and matching it to application requirements:

- Choose ceramic capacitors for high-frequency, compact, and long-life designs

- Choose tantalum capacitors when stable capacitance and size efficiency matter

- Choose electrolytic capacitors for bulk energy storage and power filtering

In many designs, engineers deliberately combine different capacitor types to balance performance, cost, and reliability.

Capacitors Difference from a Sourcing Perspective

For small and mid-sized manufacturers, the capacitors difference is not only technical, but also related to availability, lead time, and substitution flexibility.

A sourcing partner who understands both electrical characteristics and market conditions can help reduce BOM risks.

At 7setronic, we assist manufacturers by providing verified capacitor sourcing, alternative part recommendations, and fast quotation support based on real production needs.

Conclusion: Understanding Capacitors Difference Improves Reliability

The capacitors difference between ceramic, tantalum, and electrolytic capacitors lies in materials, performance limits, lifetime, and application suitability. No single capacitor type is universally optimal.

A clear understanding of capacitors difference, combined with reliable sourcing support, helps manufacturers design stable products, control costs, and avoid unnecessary redesigns during mass production.

FAQ

Q1: What is the main capacitors difference between ceramic and electrolytic capacitors?

A1: Ceramic capacitors are non-polarized and stable, while electrolytic capacitors offer much higher capacitance.

Q2: Why is derating important for tantalum capacitors?

A2: Derating reduces failure risk caused by voltage stress and improves long-term reliability.

Q3: Which capacitor type has the longest lifetime?

A3: Ceramic capacitors generally provide the longest operational lifetime.