In high-precision electronic applications, resistor selection is not a minor design detail but a core factor that directly affects system accuracy, stability, and long-term reliability. From industrial control and measurement systems to medical devices and precision power electronics, even small resistor deviations can accumulate into significant system-level errors.

This article explains how to select resistors for high-precision applications from a practical engineering perspective, focusing on electrical parameters, temperature behavior, technology choices, and real-world sourcing strategies.

Key Electrical Parameters That Define Precision Resistors

High-precision resistors are defined by more than just their nominal resistance value. Several electrical parameters together determine whether a resistor is suitable for precision applications.

Resistance Tolerance

Tolerance represents the initial accuracy at the time of manufacture. Common precision levels include ±0.1%, ±0.05%, and ±0.01%. While tighter tolerance improves initial accuracy, it does not guarantee long-term performance if other parameters are overlooked.

Temperature Coefficient of Resistance (TCR)

TCR indicates how much the resistance changes with temperature, typically expressed in ppm/°C. For high-precision applications, resistors with low TCR values (≤25 ppm/°C, and ideally ≤10 ppm/°C) are preferred, especially in environments with temperature variation.

Noise Characteristics

Low noise is critical in analog signal paths, sensor interfaces, and high-resolution ADC circuits. Thin film and metal foil resistors generally offer lower noise compared to thick film alternatives.

Power Rating and Derating

Precision resistors should not operate near their maximum rated power. Power derating reduces self-heating, which helps maintain resistance stability and minimizes thermal drift.

Temperature Effects and Long-Term Stability Considerations

Temperature variation and aging are two of the most underestimated contributors to accuracy loss in precision circuits.

Thermal Drift

Even a resistor with tight initial tolerance can drift significantly if temperature changes are not controlled. This is especially important in outdoor equipment, industrial environments, or compact PCB designs where heat accumulation is common.

Long-Term Stability

Manufacturers often specify long-term drift after 1,000 or more hours of operation. For products with multi-year lifecycles, this parameter is as important as tolerance. Thin film and metal foil resistors typically offer superior long-term stability compared to standard thick film resistors.

PCB Layout and Thermal Coupling

Resistors placed near heat-generating components can experience localized temperature rise. Proper spacing, thermal symmetry, and consistent airflow help preserve accuracy at the system level.

Select Resistors Rightly Technology for Precision Circuits

Different resistor technologies offer different balances between cost, precision, and stability.

Thick Film Resistors

Commonly used for general-purpose applications. They are cost-effective but usually have higher TCR and lower long-term stability, making them less suitable for critical precision paths.

Thin Film Resistors

Widely used in precision analog and industrial control circuits. They provide low TCR, low noise, and good long-term stability, making them a practical choice for most high-precision applications.

Metal Foil Resistors

Offer extremely low TCR and exceptional stability. These are typically used in metrology, calibration equipment, and reference circuits where maximum accuracy is required.

Selecting the right technology depends on the system’s accuracy budget, operating environment, and cost constraints.

Practical Select Resistors and Sourcing Tips for High-Precision Applications

From an engineering standpoint, resistor selection should balance performance requirements with supply chain reliability.

Application-Driven Selection

Start by defining the allowable system error, operating temperature range, and expected product lifetime. This helps determine whether ultra-high precision components are truly necessary.

Alternative Options and Cost Optimization

According to 7setronic’s project experience, for some products that may not require highly precise resistors, alternative resistors from qualified Chinese brands can be considered. Samples can be obtained first to test temperature behavior, power handling, and stability before committing to bulk orders. This approach often achieves a better balance between performance and cost without compromising reliability.

Supply Stability and Documentation

Consistent batches, traceable production, and proper documentation such as COC are critical for precision applications. Working with suppliers who can support cross-brand alternatives and long-term availability reduces risk during mass production.

7setronic supports overseas small and mid-sized manufacturers with select resistors, alternative evaluations, fast sampling, and project-based sourcing, helping engineering teams move from prototype to production with confidence.

Select Resistors Conclusion

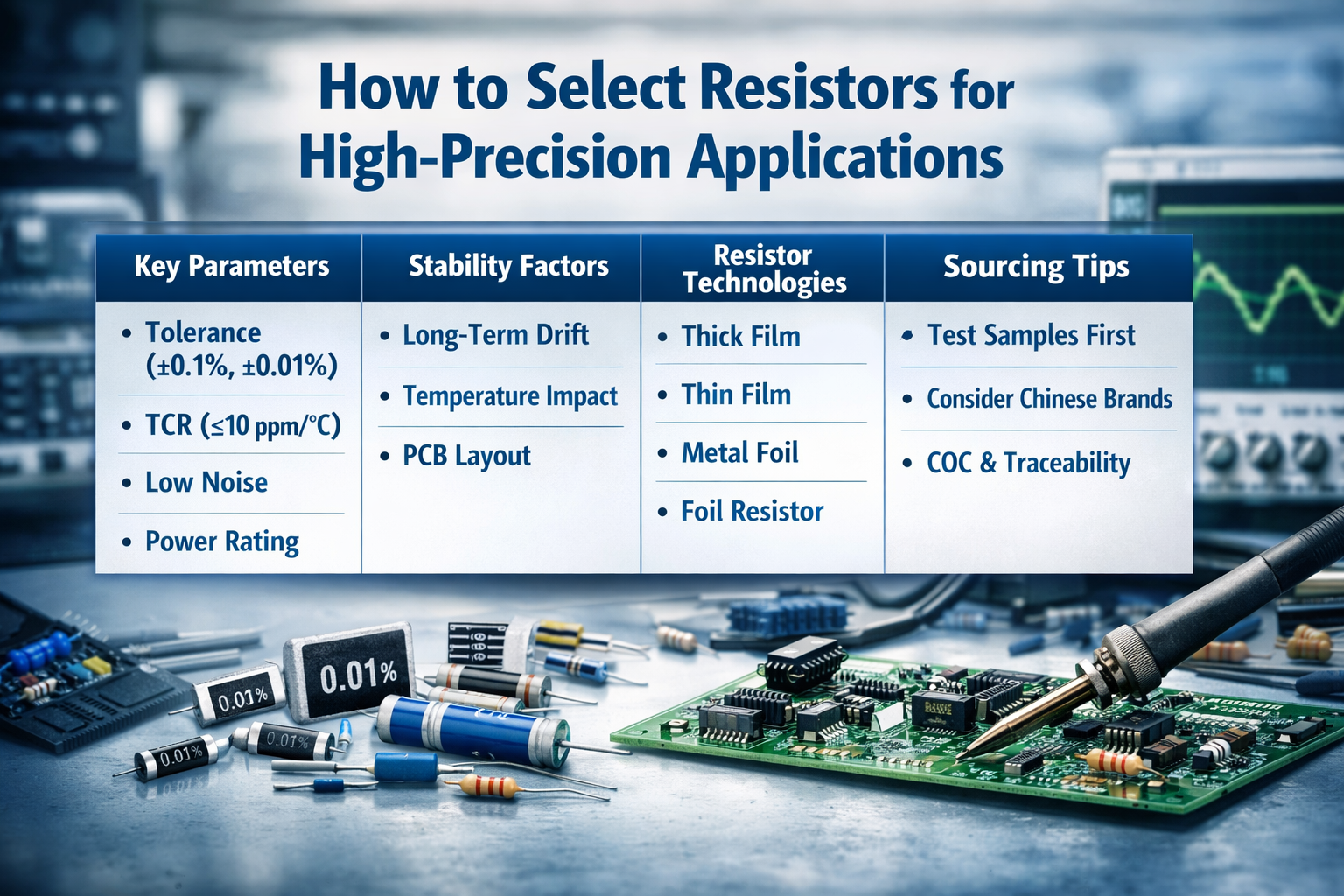

| Key Parameters | Stability Factors | Resistor Technologies | Sourcing Tips |

|---|---|---|---|

| Tolerance (±0.1%, ±0.01%) | Long-Term Drift | Thick Film | Test Samples First |

| TCR (≤10 ppm/°C) | Temperature Impact | Thin Film | Consider Chinese Brands |

| Low Noise | PCB Layout | Metal Foil | COC & Traceability |

| Power Rating | Foil Resistor |

Selecting resistors for high-precision applications requires a system-level perspective rather than focusing on a single parameter. Tolerance, TCR, long-term stability, thermal behavior, and sourcing reliability must all be evaluated together.

By combining proper resistor technology with practical validation and reliable supply support, engineers can significantly improve accuracy, reduce redesign risks, and maintain consistent product performance throughout the lifecycle.

FAQ

Q1: Is low tolerance enough for precision resistor selection?

No. TCR and long-term stability are often more important than initial tolerance.

Q2: Can Chinese-brand resistors be used in precision applications?

Yes, for non-critical precision levels, after proper sampling and validation.

Q3: Why is resistor derating important in precision circuits?

Lower operating power reduces self-heating and improves stability.

View more insights:

- How to Select Resistors for High-Precision Applications

- What Is the Capacitors Difference Between Ceramic, Tantalum, and Electrolytic Capacitors?

- NOR Flash Price Trend January 2026: TDK, ST Market Update & Supply Insights

- How Electronic Component Procurement Should Evolve with Factory Growth

- How the Passive Component Price Increase Changed After Yageo and Ta-I Joined